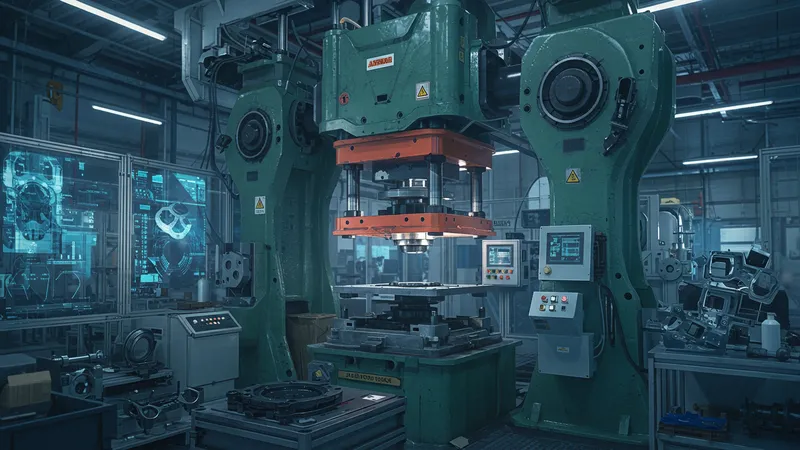

Imagine a world where nearly every product you use is crafted with pinpoint precision, all thanks to an unsung hero in the industry: the hydraulic press. This isn’t just any tool; it’s a game-changer that’s revolutionizing modern manufacturing.

As technology evolves at breakneck speed, staying informed about the tools shaping our world is crucial. Hydraulic presses are pushing the boundaries of what’s possible, impacting everything from automotive production to medical device creation.

What’s astonishing is that many industries still underestimate the potential of hydraulic presses. In sectors dominated by digital technology, these machines operate quietly yet powerfully, performing tasks that require unparalleled force and precision. Many people believe newer technology has left these machines behind, but they couldn’t be more wrong. But that’s not even the wildest part…

Consider this: items you never thought possible to manufacture with such finesse are being churned out effortlessly. Even giants like automotive and aerospace industries rely heavily on hydraulic presses to maintain safety and engineering excellence. But the secret lies in the machine’s evolution, adapting to needs no one anticipated. What happens next shocked even the experts…