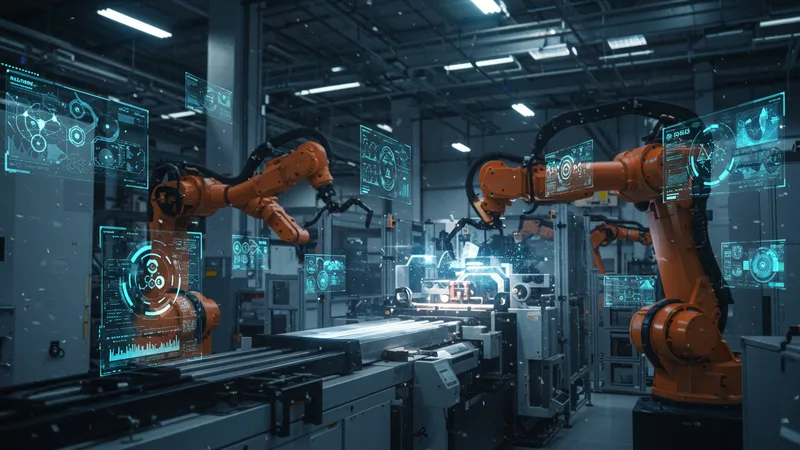

Imagine a world where machines no longer just follow commands, but anticipate needs and maximize efficiency like never before. That’s not a distant future dream—it’s happening today as innovative technologies are reshaping industrial machinery’s role in manufacturing.

Why is this transformation critical? In an era of unprecedented competition and sustainability challenges, companies that embrace cutting-edge innovations are outperforming those that resist change. The potential for growth and optimization has never been higher—missing out could mean being left behind.

What if you knew factories powered by artificial intelligence are drastically cutting waste and elevating precision? It’s a reality, yet many still underestimate the shift’s magnitude. But that’s not even the wildest part…

Revolutionary technologies like digital twins are allowing operators to simulate processes in real time, predicting outcomes and troubleshooting issues before they occur. But here’s the twist—industry experts are divided on its ultimate impact… But that’s not even the wildest part…

The next chapters reveal hidden truths behind these technologies that shocked even the experts. Are you ready to find out what happens next?